-

Design development based on basic research

-

Tenacious researchers

-

Innovation of pulverizing technique

-

Establishment of the evaluation system and introduction of equipment that were not used conventionally

Results from long-term basic research has led to an improvement in quality

| Background | A customer consulted us regarding whether we could improve the electric insulation performance of mica tape by 20% or more than the existing performance to increase the output of their product. |

|---|---|

| Challenges |

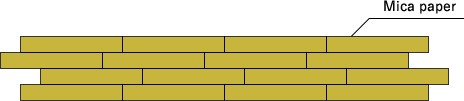

The mica tape that makes up the electrical insulation layer is made from mica foil, glass cloth and adhesive. To meet our customer’s request, we attempted an approach focused on the optimization of mica paper.

|

| Solutions |

To meet the customer’s request, glass cloths or adhesives may easily be adjusted as a minor change. |

| Conclusion |

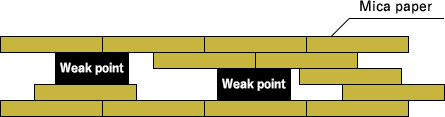

At first, we began development aimed at improving the design method. However, it was found that the conventional mica paper itself needed to be improved, and finally, a new pulverizer was used to realize the pulverization method identified through our research. We really felt that a number of accumulated patient studies through the development project led to innovation. We succeeded at eliminating the "weak point" that adversely affected the insulation performance with the originally developed pulverizer. |